Hy2Move

This European integrated project Hy2Move involves 10 projects and one associated partner. These projects were submitted by 8 Member States: Belgium (Associated Partner), Estonia, France, Germany, Italy, Netherlands, Slovakia and Spain.

Information on the individual projects can be found on the Workstream (WS) subpages.

IPCEI Hy2Move will cover a wide part of the hydrogen value chain by supporting (i) the development of innovative hydrogen-powered mobility solutions across road, rail, maritime, and air sectors, focusing on system integration, interoperability, and cross-sector synergies; (ii) the advance in high-performance, durable, and sustainable fuel cell technologies for mobility, including efforts to reduce critical materials and improve production efficiency; (iii) the focus on next-generation hydrogen storage systems with enhanced durability, safety, weight reduction, and optimised design for vehicles and aircraft; and (iv) the development of decentralised or centralised, efficient, and sustainable hydrogen production technologies tailored to mobility needs, including electrolysis and ammonia cracking systems. The IPCEI is expected to boost the decarbonisation of the mobility and transport sector, thereby reducing dependency on use of fossil fuels.

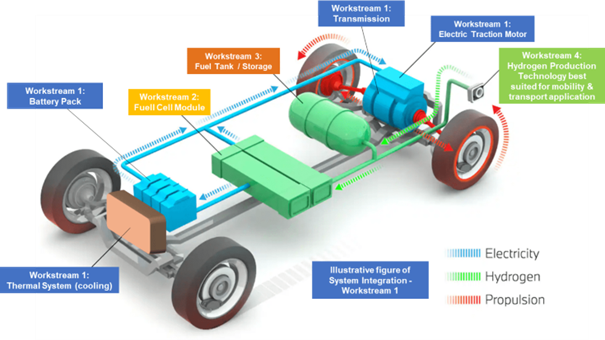

The work carried out by the Direct Participants is organised in 4 Workstreams:

- Workstream 1 – Mobility Applications

- Workstream 2 – Fuel Cell Technology for Mobility Applications

- Workstream 3 – Onboard Storage Solutions for Mobility Applications

- Workstream 4 – Hydrogen Production Technologies for Mobility

The IPCEI Hy2Move pursues the following joint overarching objectives:

- Develop interoperable hydrogen technologies and components that enable cross-application use across road, rail, maritime, and aviation sectors.

- Advance high-performance, safe, and reliable hydrogen systems, including fuel cells, storage, and production technologies, tailored to the specific demands of mobility applications.

- Promote sustainability and circularity by reducing critical materials (e.g. PGM, PFAS), improving recyclability, and enhancing environmental performance across the hydrogen value chain.

- Establish scalable, efficient, and digitalised manufacturing processes for hydrogen mobility technologies, integrating Industry 4.0 principles and enabling flexible, high-speed production.

- Ensure safety, maintainability, and system integration through robust design, predictive maintenance concepts, and compliance with commercial operation standards.

- Transfer knowledge to new or improved applications as well as new RDI in the different sectors and disseminate knowledge within the industry at large by fostering collaboration among stakeholders on overarching topics

- Create new jobs and sustainable growth in a high-potential market of the future and thereby greatly contributing to a socially just energy transition

- Coordinate and integrate Hydrogen activities in Europe in order to create a Hydrogen ecosystem

Log in

Log in

Search

Search